A sequential flow platform for multi-step chemical processes

Paper with Zaiput technology

Development of an automated platform for the synthesis, extraction, and purification of chemical compounds using optimal synthetic routes. This work bridges the gap between how chemists and chemical engineers foresee continuous synthesis platforms. Proof of concept is demonstrated with the separation of amine/alkene mixtures with similar yields to what has been obtained in batch experiments.

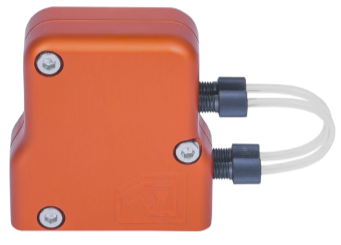

Zaiput’s SEP-10 phase separator takes a central space in the paper, by allowing continuous phase separation in a minimal footprint.

Read the full paper clicking on this link

Zaiput technology for phase separation

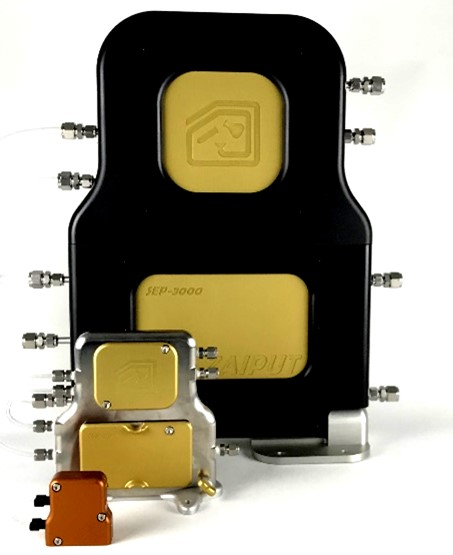

Zaiput phase separation technology is routinely used in flow chemistry applications and in flow chemistry laboratories around the world. Our membrane-based separators allow for continuous phase separation exploiting differences in the wetting properties of two immiscible or partially miscible liquids onto a porous membrane. This results in continuous, accurate, and density-independent phase separation. While the technology is primarily used for liquid-liquid separations, also gas-liquid separations can be performed with our technology, for example, to safely remove excess hydrogen after a hydrogenation.

Some of the main features of this technology are:

- Bench-top to plant scale

Our devices are well-characterized and linearly scalable from lab to pilot to production. - Separate emulsions with ease

Instead of using agitation to form microdroplets, we improve mixing by using a flow pattern that has a large surface area, thus avoiding emulsions that generally cause separation issues. Existing emulsions tend to break as they encounter the membrane. - Independent of density

The operating principle behind the technology is based on a liquid’s wettable nature, so it works with any liquid-liquid system regardless of their density difference. - Excellent chemical compatibility

Machined in materials with excellent chemical resistance, Zaiput separators work with a wide range of organic solvents, in acidic and basic solutions. - Easy usage and maintenance

Plug and play functionality at all scales. - Continuous operation for batch/flow chemistry

Our devices can be easily used and integrated within either a batch process or a continuous one - Cost effective

Our devices come at a lower price than competing technologies. Our devices also reduce your operating costs thanks to minimal maintenance and highly efficient performance. - Minimal internal volume

Our devices eliminate the need for moving or coalescing parts, and also have a drastically reduced dead volume. - Green technology

Our devices have excellent separation performance and high extraction efficiency, reducing solvent consumption. They are suitable for any chemical process, from bulk to high-value chemical industries. - Pressure rating

The metal shell design allows Zaiput separators to be used inline with a pressurized process (up to 290 psi/ 2 MPa). - Inherently safe

No electricity is required, no headspace and minimal internal volume

Finally, the separators can used in a sequence, for multi-stage extractions