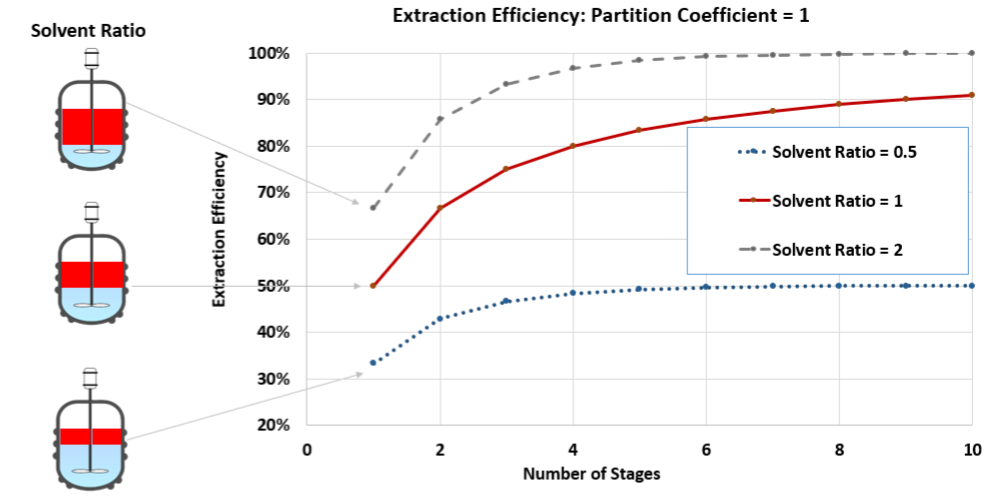

Multistage Liquid Liquid Extraction (LLE) is a process where multiple extraction steps are repeated in order to increase the recovery of a product. This process is required when, due to a small partition coefficient, the recovery in a single extraction step is insufficient.

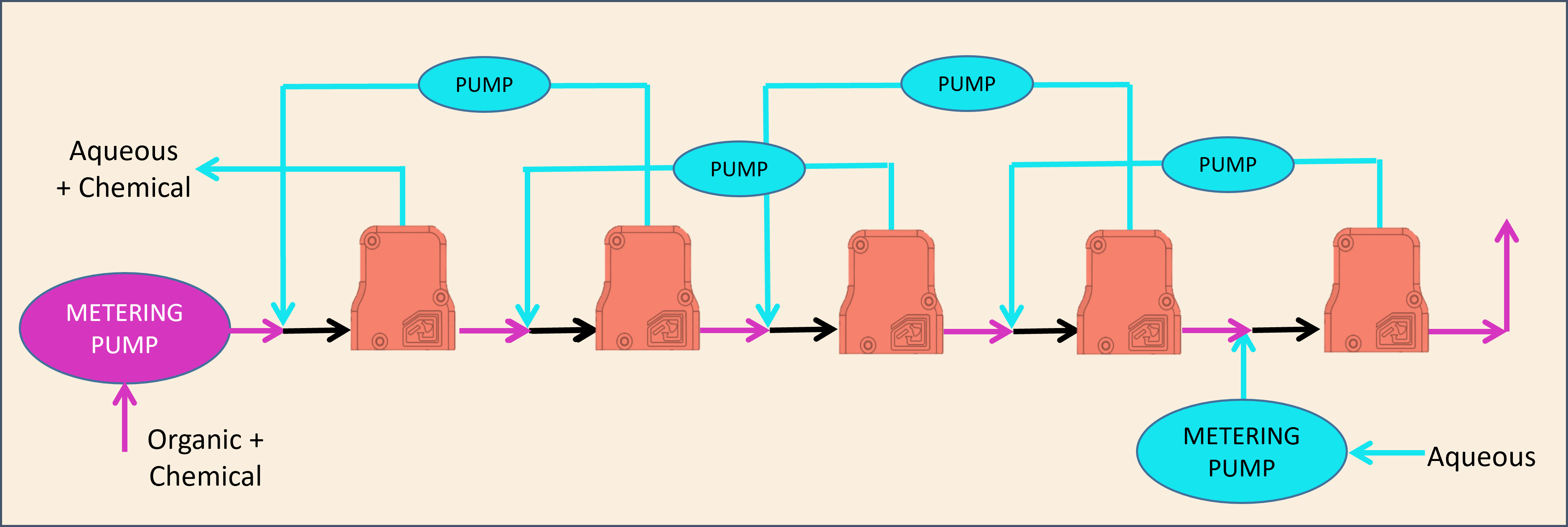

In industrial applications, LLE is most often arranged with a “countercurrent extraction scheme” (CC-LLE) that provides the smallest consumption of extractant. In this scheme, the aqueous raffinate from one stage is fed to a former stage as a feed while the organic phase is moved in the opposite direction. Hence, even if the recovery of product in each stage is small, the overall system can achieve a high level of recovery.

In other words, with multistage extraction, selectivity of the extraction and process yield are decoupled as the yield depends on the number of extraction stages used, thus providing greater freedom to the process developer.

Fig 1 – Multistage extraction efficiency

This system addresses 3 key challenges typically encountered in developing multi-stage LLE: lack of information, lack of material and difficulty in scale up.

| Technology | Mixer Settler |

Columns |

Centrifuges |

Zaiput |

|---|---|---|---|---|

| Typical Internal Volume per Stage at Lab scale (ml) | 25-100 | 150 | 100 | 3 |

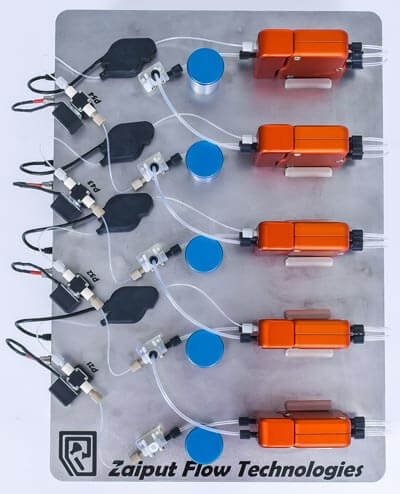

Larger throughput platforms are delivered with the amount of stages needed by your process.

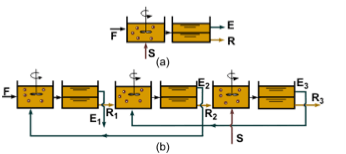

Fig 1. Schematic of the standard system plumbing

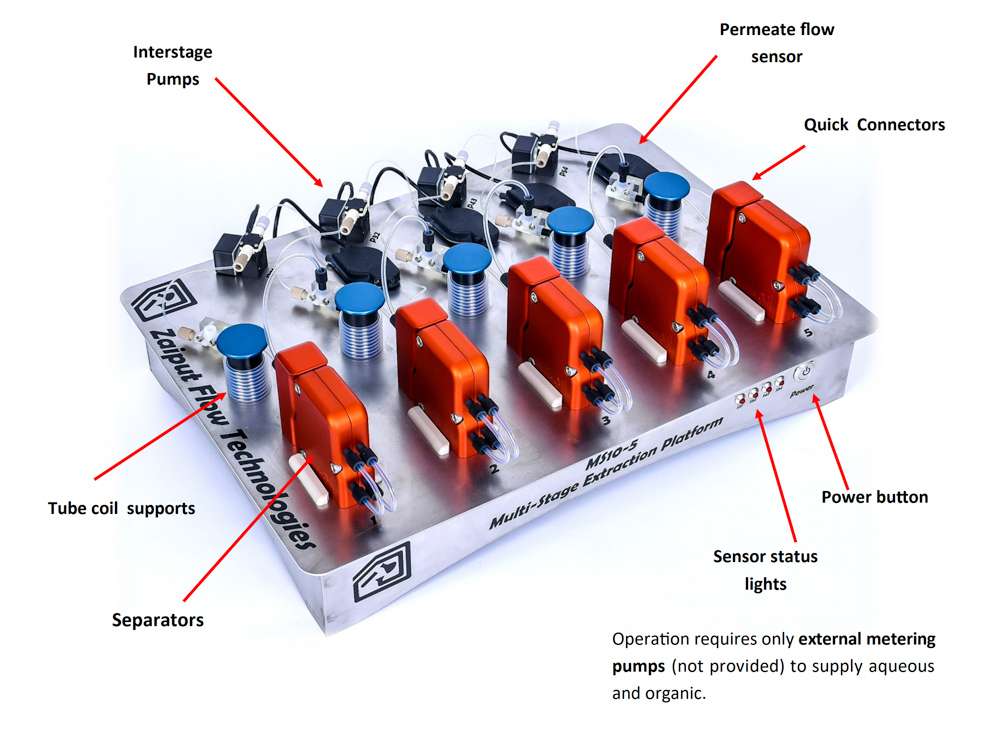

MS-10 (fig 2) captures the process shown in (fig 1) using five SEP-10s and a variety of components outlined below:

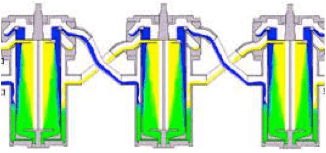

Fig 2. Multistage Liquid-Liquid Extraction Platform

Contact us if you need more than 5 stages. Platforms can be easily connected together.

|

Part Number | MS10-5 |

|---|---|---|

| Width | 500 mm (19.7 inches) | |

| Depth | 400 mm (15.7 inches) | |

| Height | 155 mm (6.1 inches) | |

| Total flow rate | 0-10 ml/min | |

| Wetted parts: | ||

| Separators | ETFE, PFA, FEP, PTFE | |

| Tubing/ flow sensors | PFA | |

| Interstage pumps | FFMK, PVDF | |

| Ports | 1/4-28 Flat bottom | |

| Max temperature of operation | 80°C | |

| Hold-up volume per stage | ~3 ml |

|

|

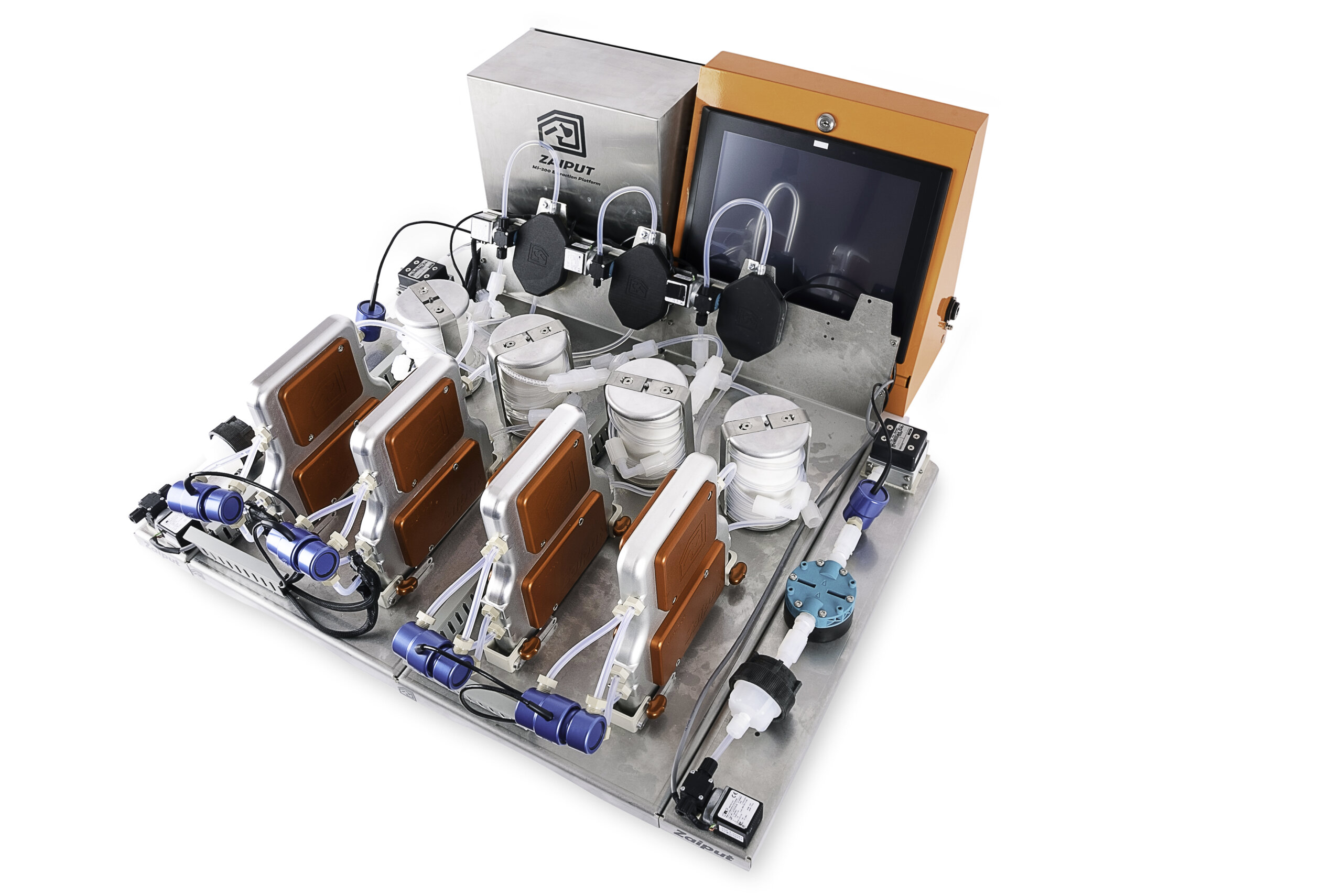

Part Number | MS200 |

|---|---|---|

| Dimensions |

Dimensions depend on number of stages specified but platforms fit in a lab hood |

|

| Total flow rate | 5 – 200 ml/min | |

| Wetted parts: | ||

| Separators | 316-SS, ETFE or Hastelloy C-276

PFA, FEP, PTFE |

|

| Tubing/ flow sensors | PFA | |

| Interstage pumps | FFMK, PVDF | |

| Ports | Swagelok for 1/4” OD | |

| Max temperature of operation | 80°C | |

| Hold-up volume per stage | ~45 ml—Depends on Setup. |

MS-3000 Platforms are custom-built to our customers’ specifications |

Part Number | MS3000 |

|---|---|---|

| Dimensions | Dimensions depend on number of stages specified | |

| Total flow rate | 200 – 3000 ml/min | |

| Wetted parts: | ||

| Separators | 316-SS, ETFE or Hastelloy C-276

PFA, FEP, PTFE |

|

| Ports | Swagelok for 3/8” OD | |

| Max temperature of operation | 80°C | |

| Hold-up volume per stage | ~500 ml – Depends on Setup |