Separators

|

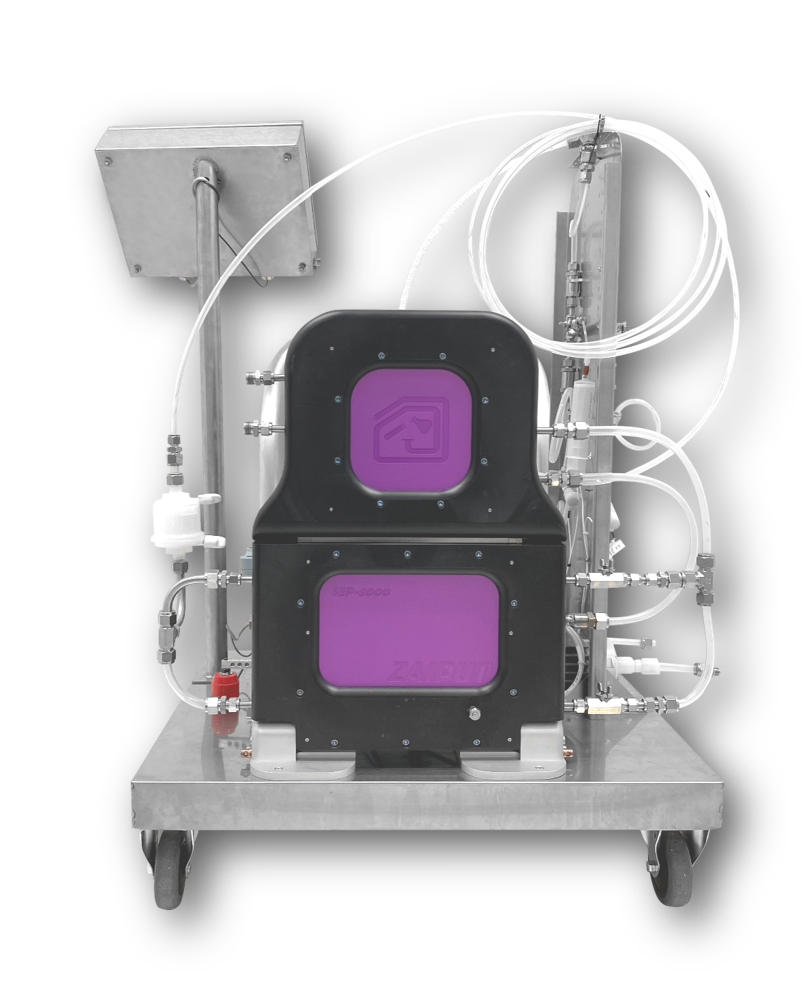

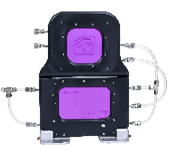

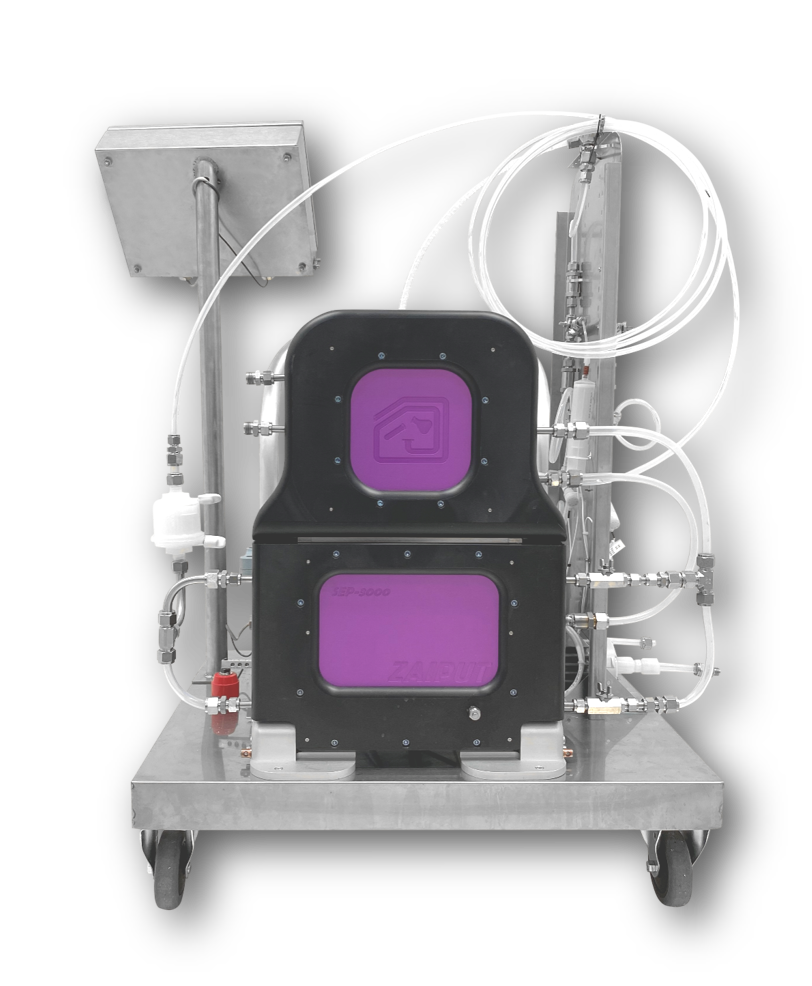

SEP-3000 | 12 L/hr – 180 L/hr |

|

SEP-40K | 60 L/hr – 2,400 L/hr |

Integrated Extraction Platforms: Pumping, Mass Transfer & Separation

|

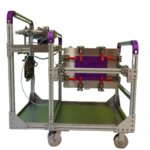

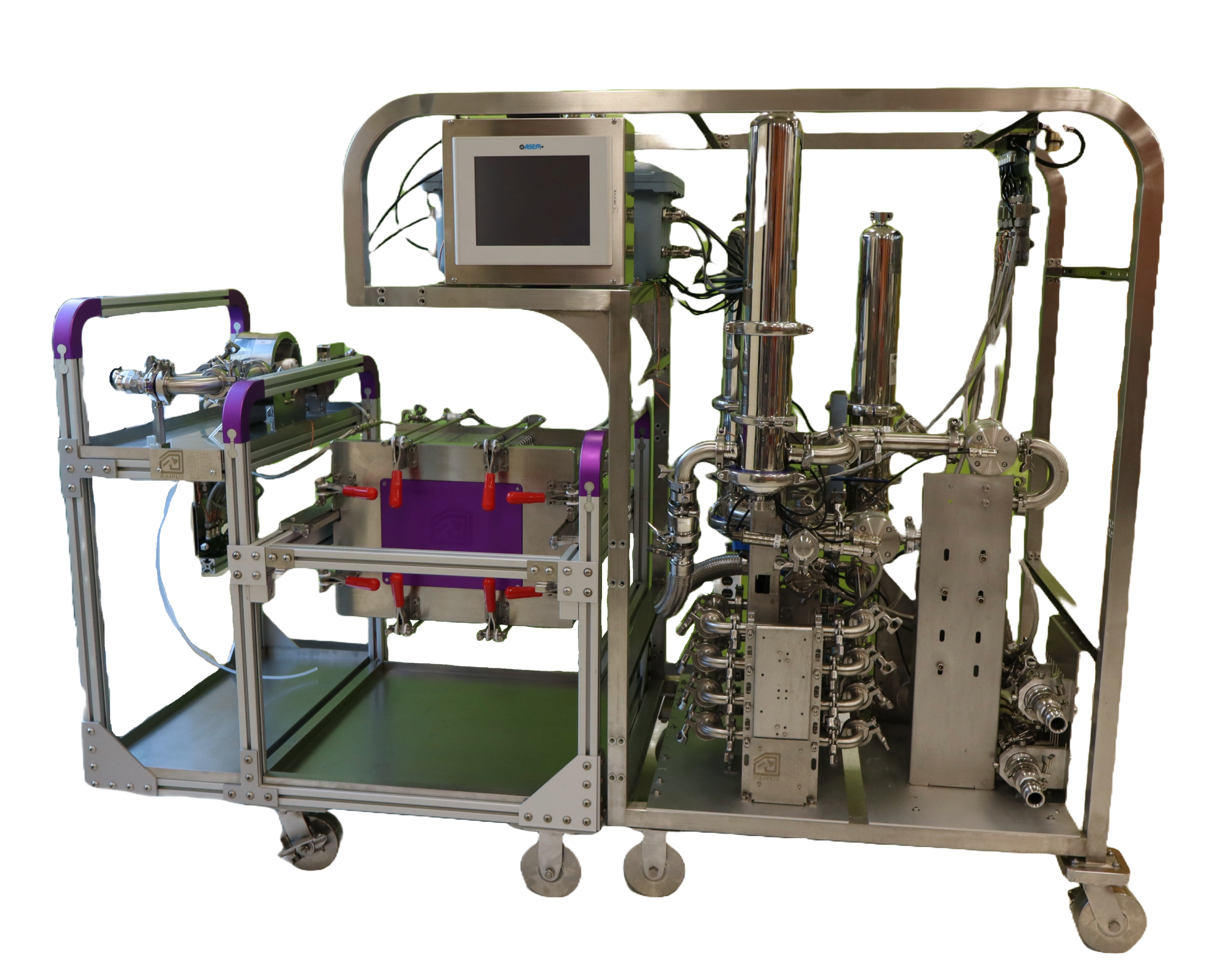

ZFOX-3000 | 12 L/hr – 180 L/hr |

|

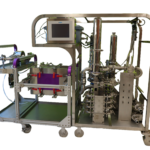

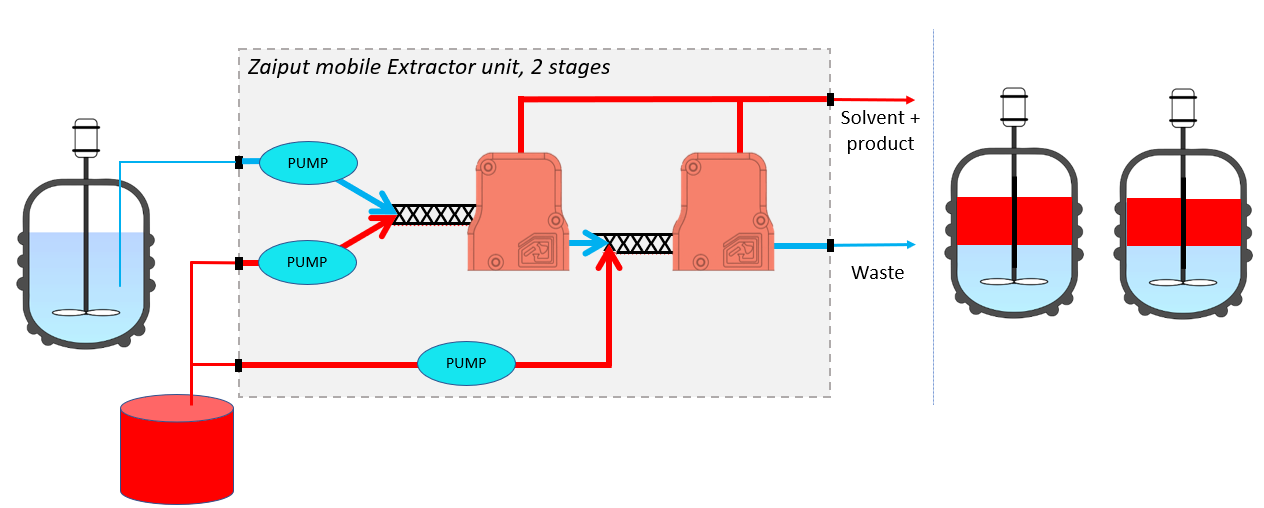

ZFOX-40K | 60 L/hr – 2,400 L/hr |

Zaiput separation technology is available at Production Scale, both as single separators for continuous or batch processes (SEP-3000, SEP-40K) and as integrated platforms for batch processes (ZFOX-3000, ZFOX-40K).

SEP-3000 and SEP-40K are the pilot and production scale versions of Zaiput’s membrane-based separators, available as plug-and-play passive separators.

Click here to discover our laboratory scale phase separators

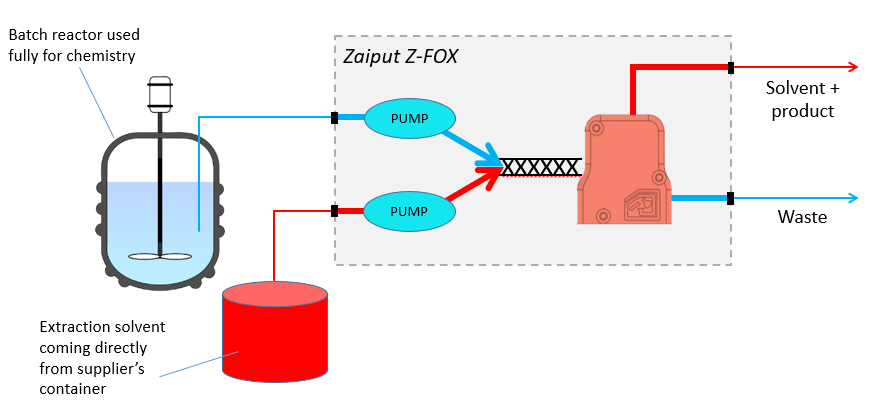

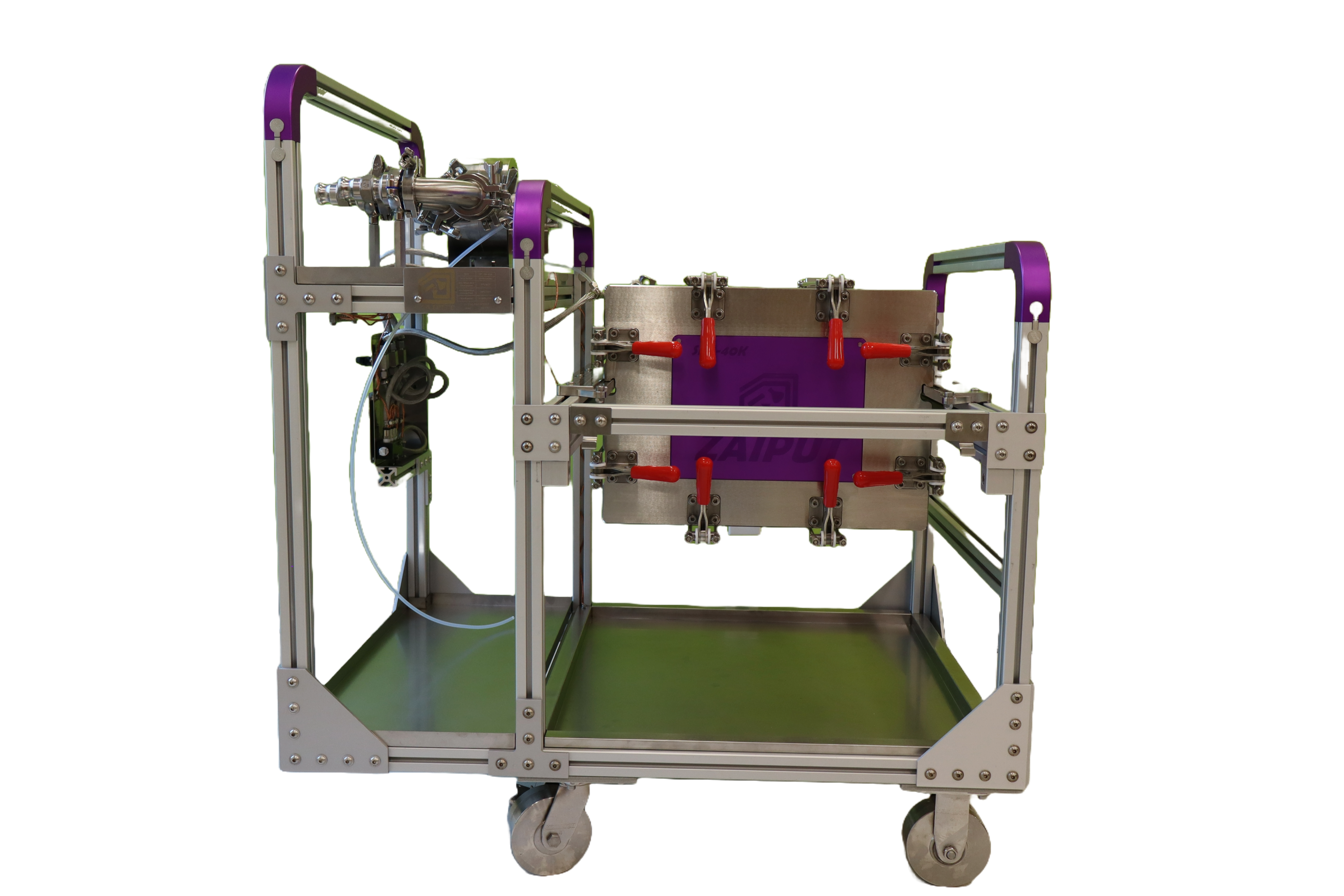

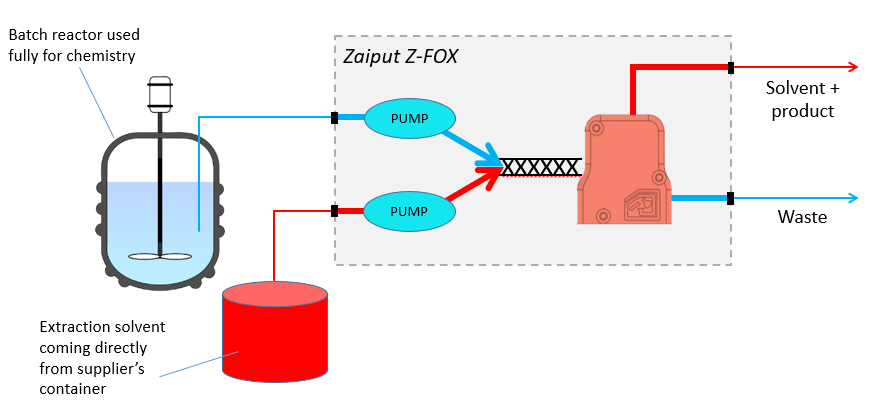

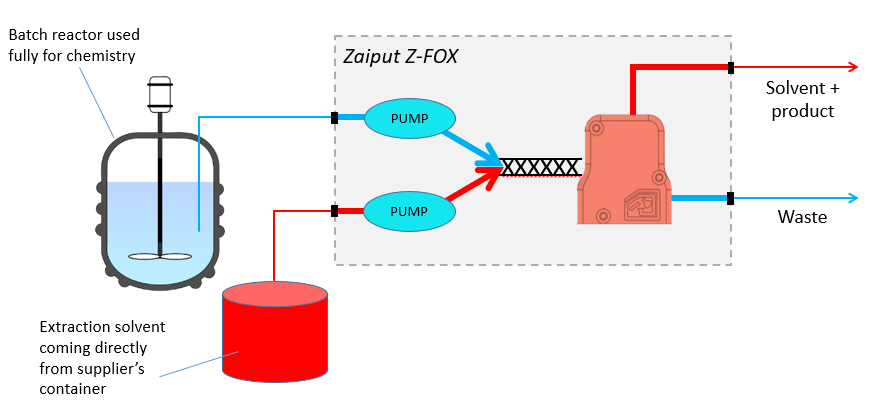

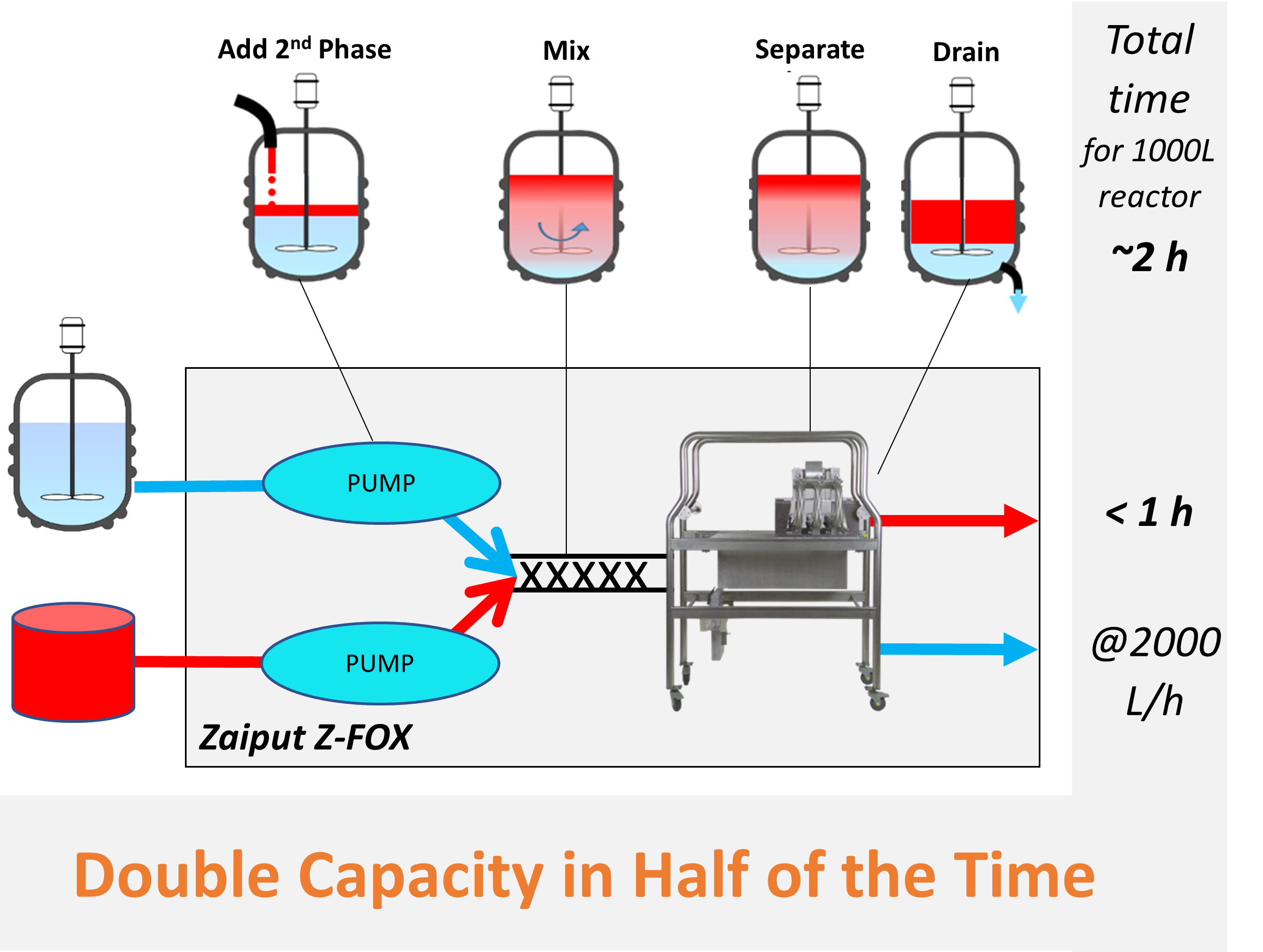

Zaiput Integrated Batch extraction platform (ZFOX) is a platform that enables a hybrid (batch + continuous) approach to solvent extraction. The platform integrates Zaiput’s phase separator with pumping, engineered mass transfer (mixing) and controls to provide a turnkey solution for plant operators. This platform addresses the major challenges of batch-based liquid-liquid extraction.

In many industrial chemical manufacturing segments (Pharma, Fine/Specialty Chemicals, etc.) liquid-liquid extraction (LLE) represents a very common post reaction purification step. Extractions are often performed in the same vessel as the reaction, relying on time consuming mixing for mass transfer and even slower gravity driven phase separation.

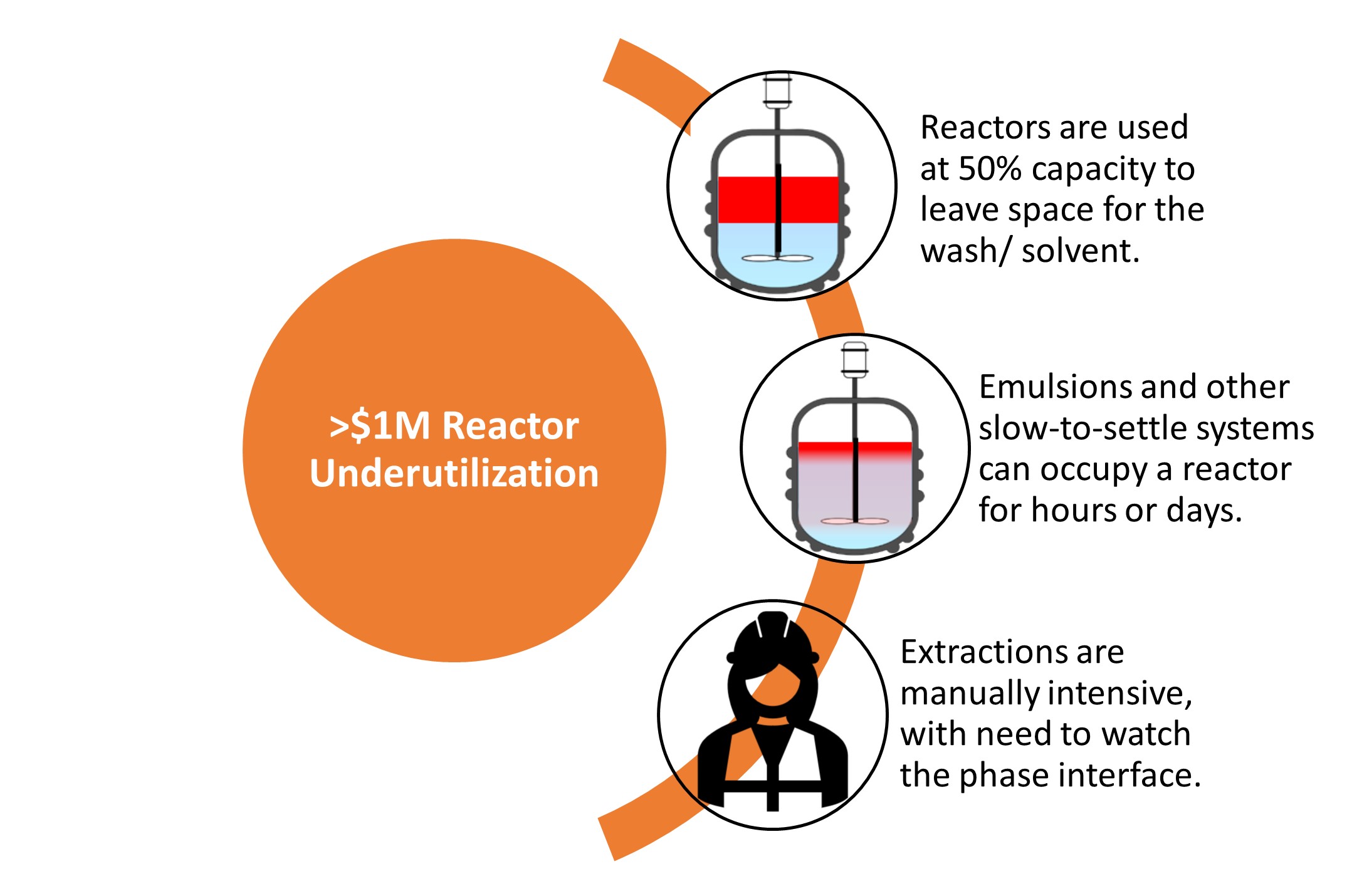

While LLE is a well-established approach, from a production standpoint, there are 3 major shortcomings:

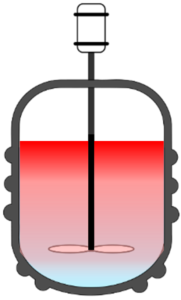

LLE in batch requires a reactor to have enough space to add the liquid phase used for the extraction. Hence when a reaction is followed by a solvent extraction, only half (or less) of the reactor volume is actually used for the reaction. This substantially reduces the productivity of a reactor, at least by a factor of 2.

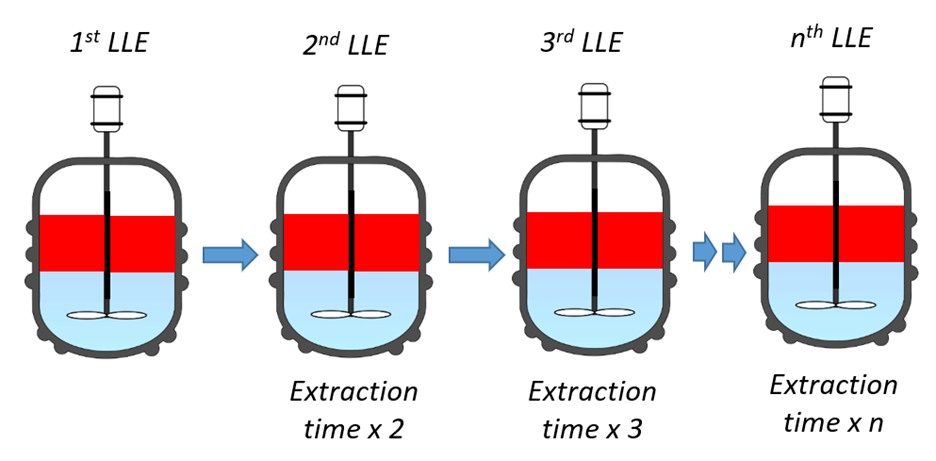

Some processes require more than one extraction (or “wash”). Besides the low productivity, the sequential nature of the multiple washes multiplies the time needed. In other words, 2 extractions need twice the time, 3 extractions need three times the time, etc. This results in a production bottle neck from a time perspective.

The current approach to LLE hinges on stirrers for mixing and on gravity as a driving force for separation of the liquid phases. Better mixing that gives smaller droplets and hence better mass transfer unfortunately results in a mixture that is harder to separate. Current approaches rely on striking a balance between better mass transfer and making systems easier to settle; this results in waste of time, material and leads to suboptimal process conditions that impact process time.

Zaiput’s Z-FOX continuous extraction platform solves these issues and more by integrating continuous membrane separation with engineered mass transfer. Now, reactors can be used to full

capacity as the extraction is taken out of the reactor, emulsions are easily and immediately separated, and multiple extractions can be carried out in the same amount of time as it takes to carry out one. Z-Fox is a small footprint, mobile platform that can easily be moved around the plant to service many reactors – a versatile continuous extraction solution to dramatically increase the output of previously installed capacity. Engineers and operators can reimagine their workflows and plant productivity with this new technology opening up a world where there is no more waiting for emulsions to settle, productivity goals are easily hit, and new extraction projects are easily scaled and implemented.

|

SEP-40K | 60 L/hr – 2,400 L/hr |

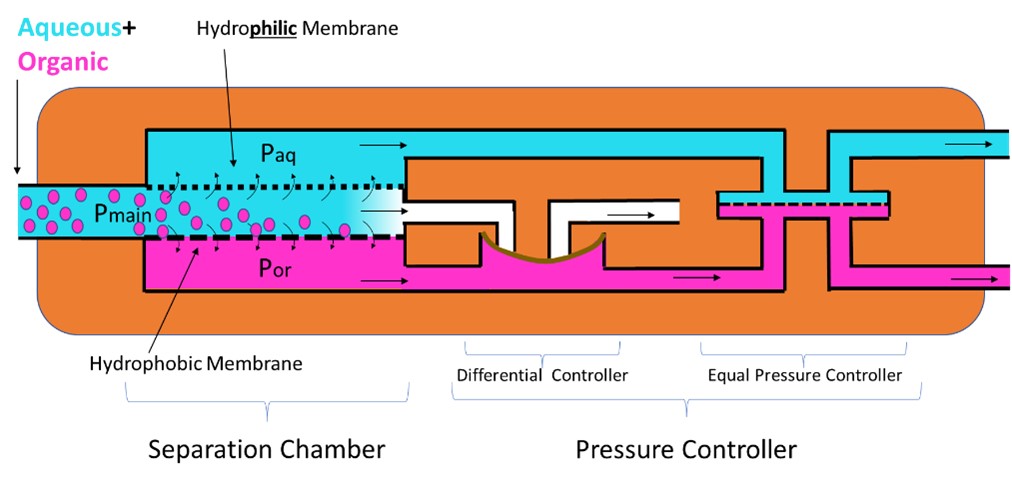

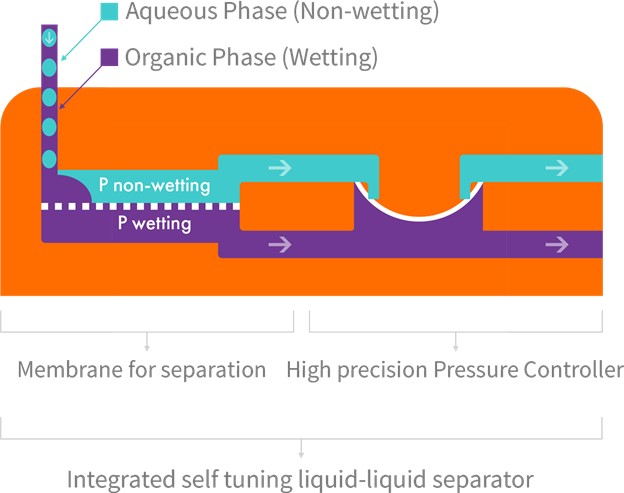

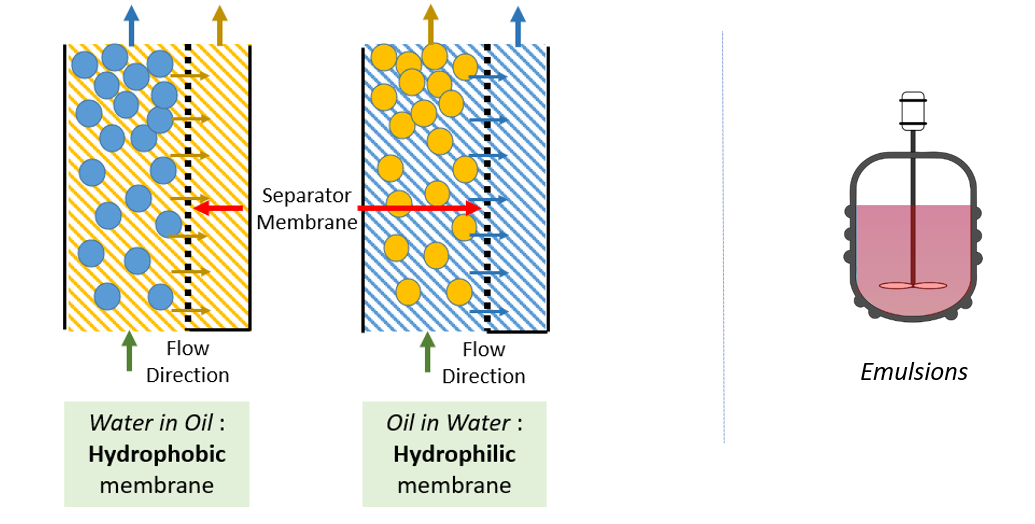

Zaiput’s liquid-liquid/liquid-gas separators work by integrating selective wetting properties of a membrane with an in-line differential pressure controller.

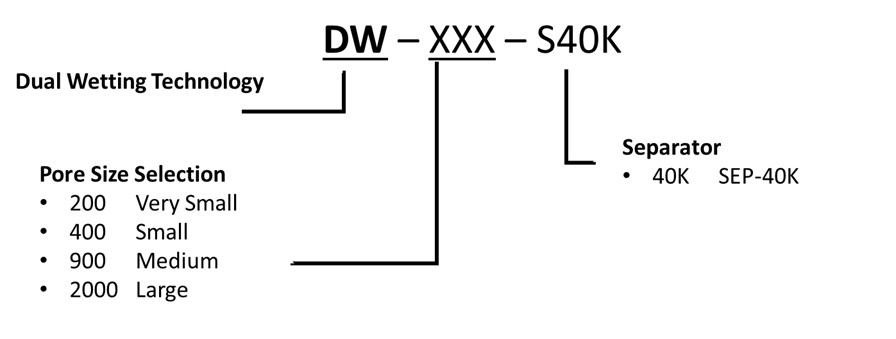

Dual Wetting Technology® (DWT):

Zaiput’s innovative separation technology DWT provides unprecedented separation efficiency for the most challenging separations.

|

SEP-3000 | 12 L/hr – 180 L/hr |

Zaiput’s liquid-liquid/liquid-gas separators work by integrating selective wetting properties of a membrane with an in-line differential pressure controller.

SINGLE WETTING TECHNOLOGY® (SWT):

|

ZFOX-3000 | 12 L/hr – 180 L/hr |

|

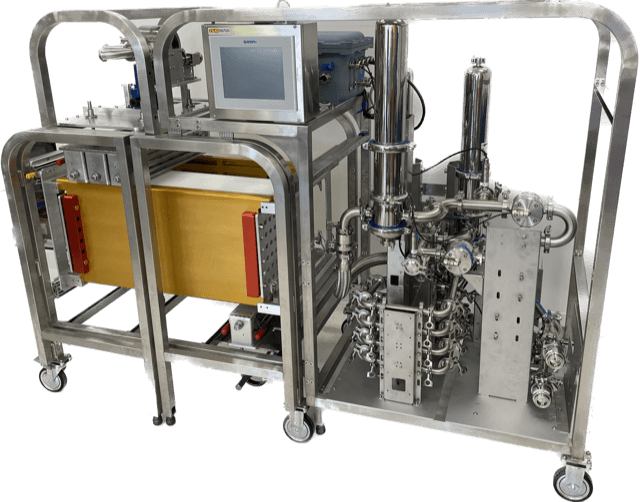

ZFOX-40K | 60 L/hr – 2,400 L/hr |

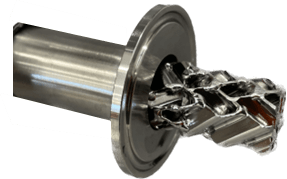

Z-FOX integrates Zaiput Flow Technologies patented separation technology with specifically engineered static mixers to provide both necessary parts of an extraction: mass transfer and phase separation.

Static Mixers are highly effective at promoting mixing between biphasic systems by forcing droplet breakup with a high degree of turbulence leading to much larger mass transfer rates than other technologies. Droplet breakup increases the surface area between phases and decreases the characteristic length needed for diffusion (radius of a droplet). Zaiput has developed a diffusion based model to determine the adequate mixing condition required to come to theoretical equilibrium for any given extractive system – for more information Click Here.

Zaiput has simplified mass transfer sizing through the introduction of “Modular Mixing Units”. An MMU contains:

To determine how many MMUs are correct for your application, please see our sizing guide here.

The engineered mass transfer and membrane-based phase separation are integrated into an easy-to-use platform for a one-stop extraction solution. The platform includes pumps, controls, and sensors specified for hazardous environments and is built on a mobile platform designed to be used across the plant.

Traditionally, extractions are carried out in the same vessel as the reaction which brings about a host of inefficiencies, most obviously the loss of capacity in a reactor.

In traditional extractions, you need to wait while mixing, settling, and decanting occurs. For reasons of purity or yield, multiple extractions or washes may be needed, requiring further solvent addition, mixing, settling, and decanting all of which dramatically slow down a process.

One of the biggest causes of inefficiencies in batch extractions is emulsion formation. Mixing must be carefully carried suboptimally in order to not emulsify a system.

Batch reactors are commonly underutilized by companies that rely on them as both reaction and extraction vessels. They are the most valuable asset in a plant, capable of producing APIs, intermediates, and other products and yet we often don’t use them to their full capacity so that we can squeeze a workup or quench into the same vessel. This underutilization is compounded across the number of reactors in a plant, leading to tens of millions of sunk cost not generating the best potential returns.

Operators and plant managers waste thousands of hours every year optimizing mixing and settling conditions, waiting for mixing to occur, waiting for emulsions to settle & watching phase interfaces while a reactor drains. All of this is wasted time that can be better utilized both in terms of people and assets.

Zaiput improves plant productivity by taking the workup out of the reactor. Instead, the workup is carried out in-line by pumping directly out of solvent storage and teeing into the product before static mixing elements. Right away, this allows plant operators to double the capacity of their reactors while taking less time to carry out their extraction. The static mixers are specifically designed to give full mass transfer while the high throughput membrane separator simplifies phase separation. Brought together you get a fast, efficient extraction in less time.

Importantly for CDMOs, this will allow companies to bring in more projects and larger projects than their current capacity allows, which will directly translate to the bottom line. The technology is applicable across a wide range of solvent systems and can be easily implemented, with minor adjustments, from process to process.

Zaiput helps engineers and plant managers hit their continuous improvement and efficiency goals across a broad range of key parameters. From increasing product output to bringing in more projects and reducing loss from difficult separations, Zaiput helps you accomplish ambitious plant improvements.

If you’re interested in any of these benefits or curious about others, email us at Sales@Zaiput.com.

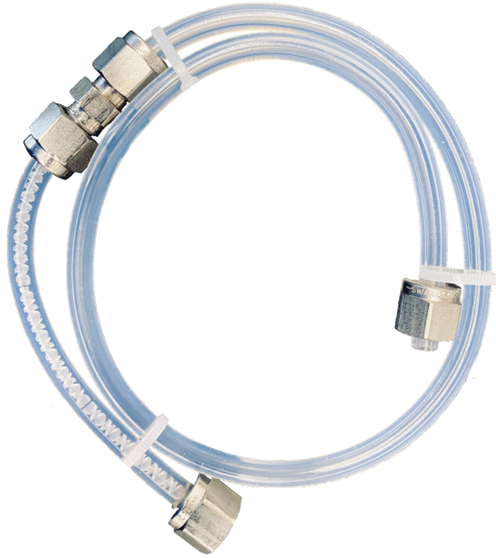

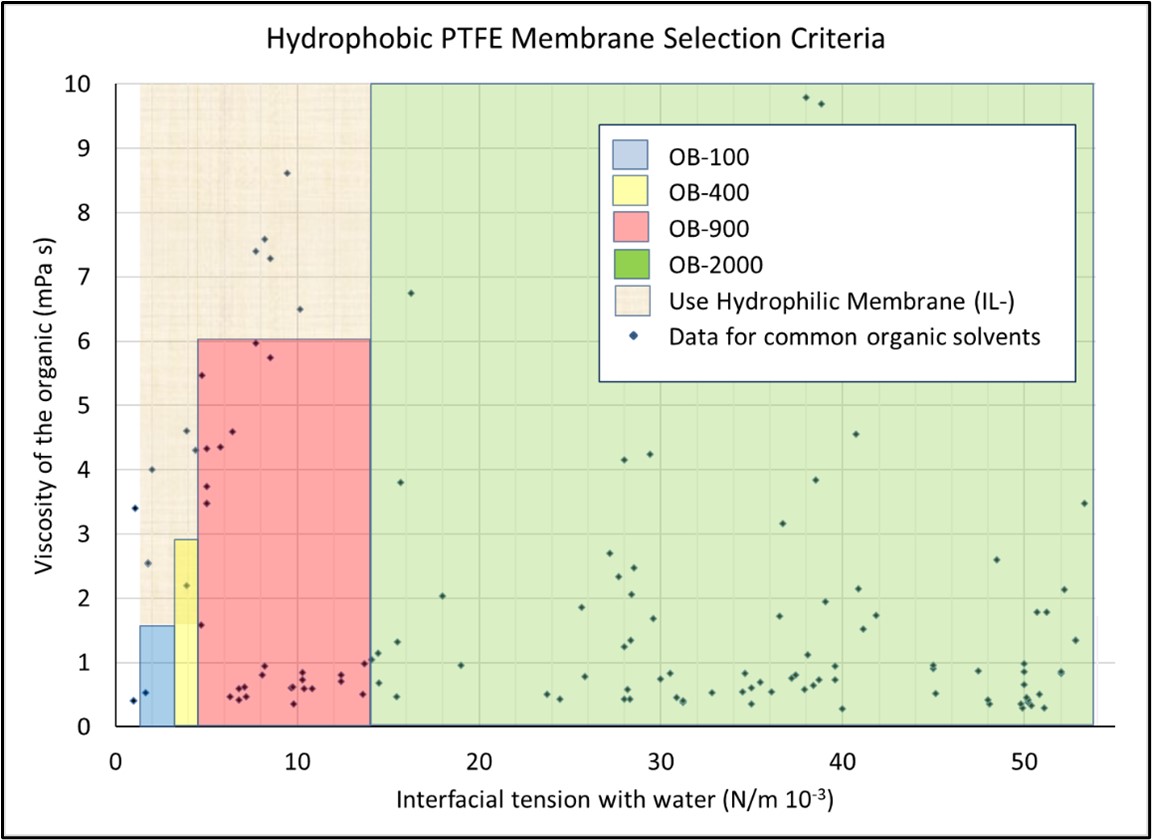

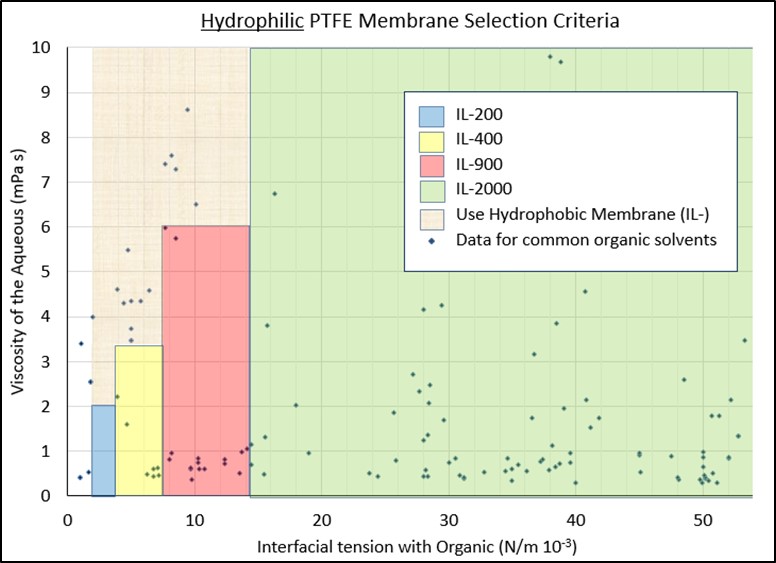

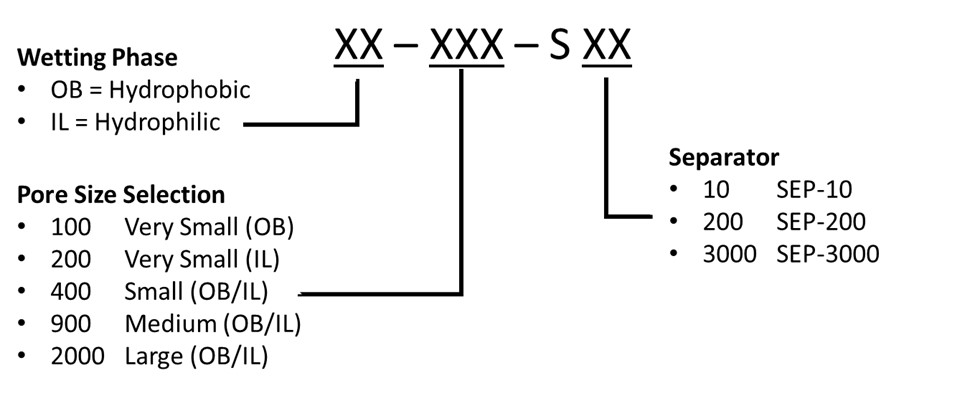

A variety of membranes for Zaiput’s separator are available to optimize separation performance and throughput. Membranes are available in both hydrophobic and hydrophilic, they are low cost and easy to replace.

The membranes for the SEP-40K are the same as the membranes for other devices except for a different, more functional packaging. The SEP-40K membranes are encapsulated in an easy-to-handle, plant-safe cartridge. The cartridge contains two membranes, one hydrophilic and one hydrophobic membrane.

Membranes for both the SEP-3000 and 40K are designed to be durable, easy to use, and low cost. They can be treated either as consumables or they can be cleaned.

Membrane selection process:

The key parameters for identifying a suitable membrane for separation are the interfacial tension between the two phases and the viscosity of the two phases (this influences the throughput of the device).

In general, the lower the interfacial tension, the smaller the pore size needs to be. However, a smaller pore size reduces the maximum viscosity that can be accommodated by the membrane. To find the membrane best for your application, please use the chart below or contact a Zaiput representative.

Contact us for the latest membrane offering

For general applications, we recommend reviewing the information in the Membrane Selection Guide.

If you have any questions, contact us at support@zaiput.com

|

||

|

||

| Part Number | Z-FOX-3000 (SS/HS/FP) | |

|---|---|---|

| Width x Depth x Height | 760 mm (29.92 inch) x 620 mm (24.41 inch) x 1150 mm (45.28 inch) | |

| Max Pressure | 1 MPa (290 psi) | |

| Ports | Swagelok for 1/2‘’ OD | |

| Separator Wetted Parts | Model HS: Hastelloy C 276, PTFE, PFA, FFKM Model SS: SS 316, PTFE, PFA, FFKM Model FP: ETFE, PTFE, PFA, FFKM |

|

| Static Mixers Wetted Parts | 316-SS, Polypropylene or PTFE | |

| Pump Wetted Parts | Customizable to fit compatibility needs | |

| Total Liquid Flow Rate | 100-3,000 ml/min | |

| Max Temperature | 130 ℃ | |

| Internal Volume | ~0.5 L | |

| Control | Stand alone & plant integrated control | |

| Filtration | Optional, different pore sizes available | |

| Compliance | Atex / Class 1 Div 2 | |

*Scroll left to see more of the table

|

||

|

||

| Part Number | Z-FOX-40k | |

|---|---|---|

| Width x Depth x Height | 214 cm x 80 cm x 160 cm | |

| Separator Wetted Parts | 316-SS, FEP, PTFE, FFKM | |

| Static Mixers Wetted Parts | PTFE, 316-SS, or PP | |

| Pump Wetted Parts | Customizable to fit compatibility needs | |

| Total Liquid Flow Rate | 60—2400 L/h | |

| Internal Volume | Varies with # of Cartridges used | |

| Control | PLC-based, can be integrated with plant control | |

| Filtration | Optional, different pore sizes available | |

| Compliance | Atex / Class 1 Div 2 (upon request) | |

*Scroll left to see more of the table